Applications Claiming Priority (

Applications Claiming Priority ( Two forms of tank sealant are offered, liner and mastic; the most typical being the liner sealed design. The within the tank shell is lined with a synthetic EPDM, strengthened PVC or butyl rubber liner. The purpose of the liner is to separate the water from the tank shell. The concrete base and shell are also lined with geo-textile matting to provide extra safety in opposition to damage to the liner. Park building progress, announcements, and schedule updates will be posted on and

Beaverdam Reservoir

It is crucial to rotate the mass of oil beneath regular working conditions to maintain particles, water, and different international contaminants from settling. In this manner, contamination is saved suspended in the oil till it's caught in a filter. Most of the contamination is taken out of circulation the primary time it encounters a filter. Furthermore, filters are a lot easier to hold up than reservoirs are. Replacing a dirty filter factor has turn into simpler and extra handy than ever, and indicators make it simple to find out when an element needs to be modified.

Register Now for Nature Summer Camps!

After the initial draw down of the reservoir’s water stage final fall to finish pier structures, the reservoir is now refilling naturally. Once water ranges are secure to allow recreational actions, water entry will be reopened at the Mt. Hope Road entry level. Better by design A secondary good thing about vertically oriented cylindrical reservoirs is best utilization of the supplies than with conventional designs — particularly when bigger reservoirs are required. When the reservoir should exceed roughly one meter in height, hydrostatic stress of the liquid column has to be considered to forestall the reservoir’s side plates from deflecting outward. To scale back or forestall bulging and strain within the material, designers typically specify corrugated aspect plates or heavy gauge metal for developing the reservoir, or they specify ribs for added stiffness. Furthermore, locating them inside the reservoir creates corners and crevices that acquire contamination.

Tank solutions and services

When the return flow enters the reservoir, the entire mass of oil tends to slowly rotate. On normal galvanized tank designs, the coating of the tank shell doesn’t mean a discount of the galvanized zinc coatings, the epoxy and polyester coatings are in addition to the galvanizing process. NOVA Parks and Loudoun Water are happy to announce that on-water leisure activities on Beaverdam Reservoir will re-open on Monday, April 1. Reservoir Park remains to be an lively development web site with heavy gear, subsequently it is unsafe for pedestrians and motorists to enter the new park web site, and access remains prohibited. The public will only be capable of access the reservoir from the Mt. Hope Road parking space. Please note that parking may be restricted and that boating and/or coming ashore in areas close to the Reservoir Park building space is prohibited.

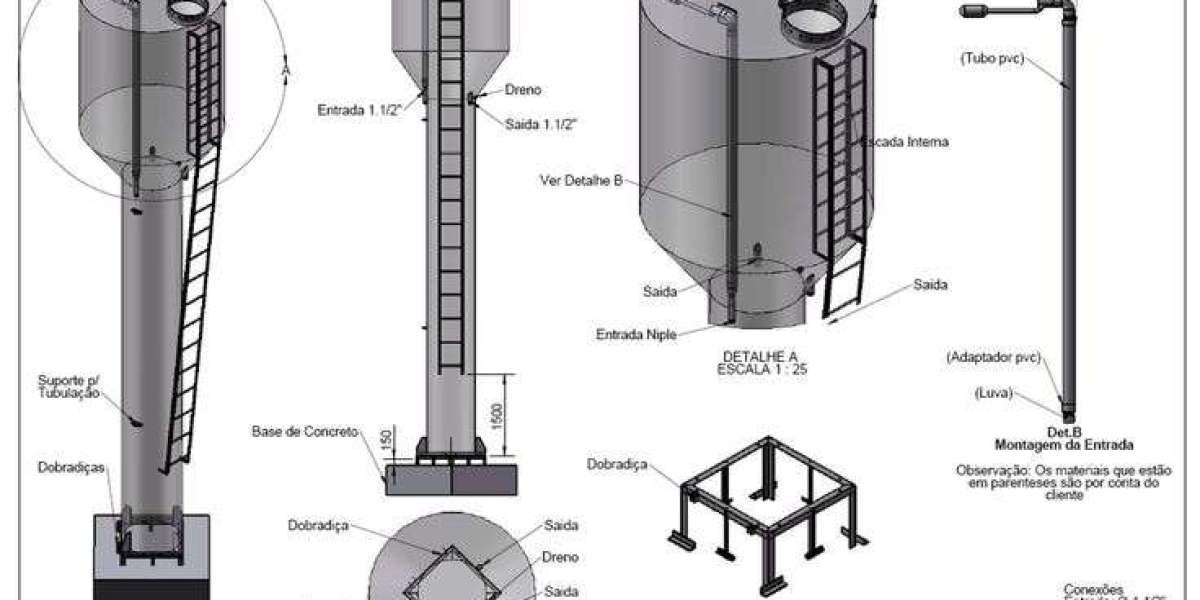

Design Your Own Side Mounted Cylindrical Tank

A cylindrical reservoir with the identical peak and volume would have a diameter of about 2.55 m. With the cubic reservoir, aspect plates would have to be 14 mm thick to face up to the hydrostatic stress from a column of oil, and bulging could be roughly 15 mm. On the other hand, plate thickness for the cylindrical reservoir would only should be zero.25 mm or less. Furthermore, diametral deformation from hydrostatic pressure can be only about 1 mm.

Fuel Tanks

For specialised purposes aluminium and stainless steel tank choices are available. For instance, letting contaminants settle onto the underside of the reservoir retains them in steady contact with the fluid, thereby affecting its chemistry. Moreover, the floor of this sediment layer may be very unstable, so a change within the return oil flow rate or path can stir up clouds of contamination within the otherwise clean fluid. Even with careful flow regulation, stirring up this sediment layer can't be avoided in cellular and marine purposes. Most of the attention paid to preserving hydraulic methods working clean has centered on preliminary flushing adopted by steady and off-line filtration. Electrostatic filtering and centrifuge purification have emerged as extra intense strategies that take away even the smallest particles, oxidation merchandise, and water from hydraulic fluid. However, chemical activity between contaminants and the fluid tends to speed up breakdown of the fluid by producing aging merchandise.

Finally, caixa d água taçA 15000 litros you will want to consider the price of a plumber to connect the pipes. If you’re wanting any additional add-ons on your water tank, similar to booster pumps to extend the water strain, there could additionally be extra prices to consider. If you’re just in search of an estimate, a easy rule of thumb is to allow between 40 litres for every occupant in the house – in order a very tough guide, a family of four folks could use round one hundred sixty litres of sizzling water. However, this must be used as a very basic guide and may not precisely match your scorching water needs. If the position of the outlet is required in an alternative place to the usual one offered or extra to the one positioned, we will offer a plastic Fusion socket. This could be welded anyplace on the tank utilizing a drawing provided by us, positions marked out by you, then fitted by the manufacturer. Calculate the delivery price of your water tank or take a glance at our provide and set up service in NSW Metro areas.

Finally, caixa d água taçA 15000 litros you will want to consider the price of a plumber to connect the pipes. If you’re wanting any additional add-ons on your water tank, similar to booster pumps to extend the water strain, there could additionally be extra prices to consider. If you’re just in search of an estimate, a easy rule of thumb is to allow between 40 litres for every occupant in the house – in order a very tough guide, a family of four folks could use round one hundred sixty litres of sizzling water. However, this must be used as a very basic guide and may not precisely match your scorching water needs. If the position of the outlet is required in an alternative place to the usual one offered or extra to the one positioned, we will offer a plastic Fusion socket. This could be welded anyplace on the tank utilizing a drawing provided by us, positions marked out by you, then fitted by the manufacturer. Calculate the delivery price of your water tank or take a glance at our provide and set up service in NSW Metro areas.